MS Series

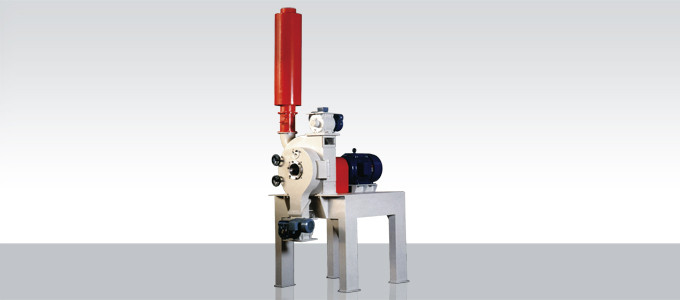

MS 370 microclassifier is a machine for the classification of fine products, with a minimum top cut of 5 µm, present in already ground powders products.

The classifier is of the fixed cage dynamic type.

The classification of the particles is carried out by applying contrary forces on them, this way causing the separation of granules according to their diameter.

The feeding dosage takes place by a screw controlled by a processing regulator which keeps the consumption of the main motors within a highly efficient range.

The introduction of the material in the microclassifier takes place by a rotary valve.

The constant-speed rotor is adjustable by frequency converter and it gives centrifugal force to the material being fed. The airflow caused by the suction drags the material in the opposite direction to the centrifugal push.

It is possible to choose the granulometry of the final product by varying the rotor speed.

The higher the density of the material, the more efficient the classifier action, therefore obtaining lower top-cuts.

The fine fraction is extracted by suction by a non-stop high head fan and the reclaiming is carried out by a self-cleaning bag filter.

All the material with a diameter wider than the chosen value is discharged by the microclassifier by the rotary valve. According to the market request, the material can be sold as it is or ground again.

All operating parameters are adjustable and shown on the operating panel.

The granulometry can be changed without stopping the equipment.

- MS microclassifiers are very contained machines in terms of size and weight which are supplied already assembled on their own easy-to-anchor bed

- Dynamic squirrel-cage classifier

- The classification rotor speed is variable according to the top-cut.

- This type of equipment requires a high head fan specifically dimensioned with the triple aim to suck the material from the machine, allow the dynamic selection of powders and the pneumatic conveying to the bag filter.

- The fine fraction is extracted by continuous suction.

- The recovery of fine parts is entrusted to a self-cleaning bag filter.

- The fraction exceeding top-cut is unloaded by a rotary valve.

- All operating parameters are adjustable and shown on the operating panel. The granulometry can be changed without stopping the equipment.

- Choice of materials of mechanical parts (Carbon steel or carbide coated steel, AISI 316 steel or special steels which have undergone special heat treatments) according to the application field.

- High separating efficiency with consequent reduction of loss of fine parts in the waste

- Limited size, weight and power

- Easy installation and maintenance

- Possibility to change the granulometry of the product without stopping production.

- They can also be used downstream classifier mills to even more increase the percentage of fine particles into the product

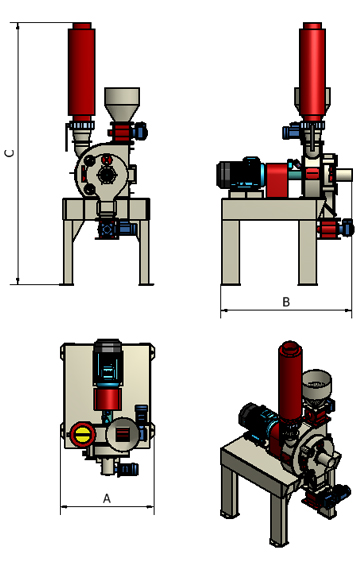

| >>> DOWNLOAD DATASHEET | MS 370 | |

| Microclassifier | ||

|---|---|---|

| Dimensions A mm | 1090 | |

| Dimensions B mm | 1530 | |

| Dimensions C mm | 3050 | |

| Total weight kg | 960 | |

| Power supply | ||

| Classifier kW | 22 | |

| Rotary valve inlet product kW | 0.75 | |

| Rotary valve outlet product kW | 0.75 | |