Distribution - Dosage

An efficient storage, extracting and dosing system allows the best handling of this delicate step of the micronization process by:

- Smooth feeding and right distribution of the product which allows to avoid stopping the process further on and discontinuous and/or bad feeding.

- Control and check of the quantity of the processed material, the visualization/collection of actual data of the weight resulting in the removal of over or underdosage.

G.T.S. identifies and designs the most suitable solutions in order to develop the most appropriate and efficient distribution and dosage system of the material: from simple and inexpensive dosing systems to complete and elaborate distribution systems which can simultaneously feed more than one weight-control dosing line.

The optimization and the control of the dosing process therefore allow a uniform distribution on the various feeding points and the control of the weight of the processed material.

Where the market has failed to supply appropriate technology, G.T.S. has improved existing machines, in cooperation with the technical staff of some selected Suppliers, by designing and manufacturing components and innovative machines for the solution of problems highlighted by Customers, deriving from specific characteristics of the products and its management.

Reversible screws, diverter valves and Y-joints are the most suitable options for less complex systems.

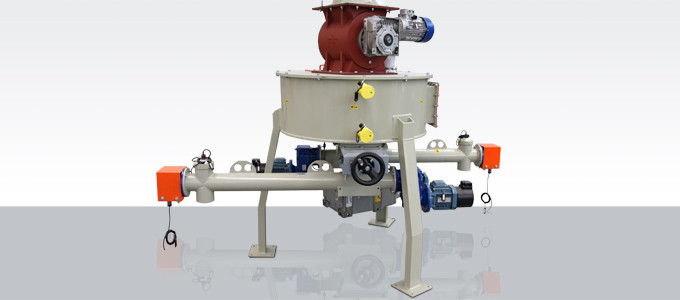

The DS series distributor is a versatile machine which allows the homogeneous distribution on more than one line of powder, sand or granular materials with a maximum diameter of maximum 20 mm, chemically stable and non-flammable.

An ATEX version, suitable for explosive materials such as activated carbons is available.

The material enters the distributor by a conveying screw or a rotary valve; inside a blending tool with steel blades is installed, which facilitate the descent of the material by dropping it into two or more drainage mouths.

This tool is activated by a motorgear installed under the distributor.

Manual slide valves have been designed to help maintenance operations.

Finally, the material is distributed and conveyed by tubular screws to the various feeding points.

- Made in carbonated steel with appropriate surface coat or in stainless steel.

- Two limit switches are installed on the lid and on the lateral wall, and a filter bag is installed on the upper part.

- On each opening at the bottom a manual slide and an extracting-dosing screw are installed.

- The dosing screw is equipped with motorgear adjustable by frequency converter in order to change the dosage and forced ventilation motors in order to assure good functioning even at low regime.

Advantages

- Uniform distribution to the various feeding points

- Improvement of the reliability of the dosing system

- Possibility of weight control of the system using a weighing platform

- One only storage point can homogeneously feed more than one feeding line at a time.

Technical data

DS-1000

Distributor dimensions: mm Ø 1050 x h 360

Distributor volume: 0,31 m3

Min height: mm 1200

Max height: variable

DS-800

Distributor dimensions: mm Ø 800 x h 205

Distributor volume: 0,10 m3

Min height.:mm 1200

Max height.: variable

Micro dosing screws for the volume dosage suitably adapted to the specific production requirements thanks to the know-how acquired in years of experience in the sector.

- Micro dosing screw equipped with hopper and vibration level switch.

- Hopper lid equipped with a joint to the feeding screw and a stub pipe equipped with a filter bag to compensate pressure.

- The screw motor is powered by a converter and it is force-ventilated in order to improve its functioning at low speed.

- The machine frame, the dosing screw and the blending tool are made of stainless steel.

- Two different motors for the blending tool and the dosing screw.

Tubular screw for the volumetric dosage based on a versatile and inexpensive dosing system. An ATEX version of the screw is available.

- Screw equipped with tubular coat, rotating spiral and sealed heads.

- Its motor is chosen for the application of the screw, it is powered by frequency converter and force- ventilated in order to improve its functioning at low speed.

- The ATEX version dosing screw ATEX version is made in stainless steel.