MG•P Series

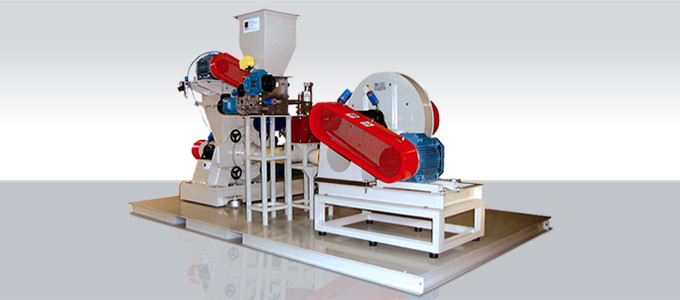

The MG•P classifier mill is a patented model specifically developed for the micronization of sodium salts used in the process for the neutralization of emissions in the atmosphere.

The MG•P classifier mill uses an uncrossed fan which does not require to stop the machine for its cleaning. There is no necessity for the stops, too often delayed for too long and therefore causing malfunctioning, typical of other mills.

The grinding takes place by high peripheral speed impact, with fixed grinders, in a circuit closed by a dynamic classifier.

The adequate modification to the geometry of the grinding chamber allows the mill to operate in light pressure, giving the material hit by the hammers paths which are perpendicular to the impact surface of the grinding armor.

The horizontal rotation axis allows an easy and quick opening of the grinding chamber, and makes the extraction of the mechanical components easier.

A dynamic classifier, situated on the part above the grinding chamber, allows the continuous control of the final granulometry of the product.

It is made up of a “squirrel cage” wheel which the material must go through in order to leave the classifier mill. The cage gives the particles a centrifugal force opposite to the kinetic force applied by the airflow on the particles.

By operating on the rotation speed it is possible to change the Top-Cut diameter of the product, that is the maximum diameter of the particles allowed to leave the Classifier Mill.

The fineness regulation takes place by varying the classifier speed without interrupting the production, the control software of the electric switchboard PLC automatically changes the classifier turns according to the feeding value.

In best conditions of use and maintenance G.T.S. plants guarantee service availability of 8200 hours/year.

- The one rotor classifier mill is a compact machine which is supplied already assembled on its own easy-to-anchor bed

- The feeding dosage takes place by a screw controlled by a process regulator (PID) which changes the material quantity according to the acidity values detected by working on the motor frequency converter.

- The particular position of the feeding allows the installment of the dosing system on loading cells and its weight control.

- The speed of the grinding rotor is set according to the processed material and it is constant.

- The RPM of the classifier can be changed while the machine is working and the value is shown on the relative panel display.

- A high head fan is required, specifically dimensioned for the following three objectives:

- Avoid the machine overheating

- Handle the material from the grinding chamber

- Allow the dynamic selection of powders

- Working conditions in order to obtain the desired finesse are set and displayed on the operating panel.

- The innovative use of the uncrossed fan allows the use of more efficient impellers.

- Uncrossed fan: no cleaning required

- Further reduced maintenance

- Limited size and weight

- Easy installation

- Change of the product granulometry without stopping the production

- Possibility to adapt the weight control of the feeding

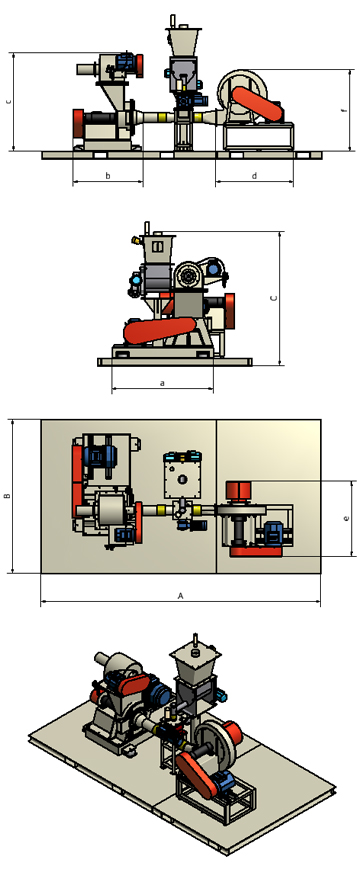

| NOMINAL OUTPUT for Sodium Bicarbonate – (kg/h) min - max | |||

| PARTICLE SIZE | MG•P 30 | MG•P 40 | MG•P 60 |

|---|---|---|---|

| d90 ≤ 35 µm | 20 ÷ 200 | 50 ÷ 600 | 100 ÷ 1200 |

| d90 ≤ 20 µm | 120 | 300 | 600 |

| >>> DOWNLOAD DATASHEET | MG•P 30 | MG•P 40 | MG•P 60 |

| Classifier Mill | |||

|---|---|---|---|

| Dimensions a mm | 1070 | 1450 | 1600 |

| Dimensions b mm | 900 | 1000 | 1200 |

| Dimensions c mm | 1250 | 1410 | 1790 |

| Micro-dosing feeder | |||

| Hopper capacity dm3 | 80 | 80 | 80 |

| Screw power kW | 0.75 | 0.75 | 0.75 |

| Forced ventilation kW | 0.02 | 0.02 | 0.02 |

| Blending tool power kW | 0.75 | 0.75 | 0.75 |

| Fan | |||

| Dimensions d mm | 1100 | 1120 | 1430 |

| Dimensions e mm | 1050 | 1050 | 1150 |

| Dimensions f mm | 1100 | 1200 | 1430 |

| Total pressure mm/H20 | 500 | 600 | 900 |

| Air volume m3/h | 720 | 1500 | 3000 |

| Transport piping | DN 125 | DN 150 | DN 200 |

| Standard base dimensions | |||

| A x B x C mm | 4000x2200x2260 | 4000x2200x2260 | 4500x2200x2260 |

| Weight with motors kg | 1800 | 2100 | 3100 |

| Power supply | |||

| Grinder kW | 11 | 18.5 ÷ 22 | 30 ÷ 37 |

| Classifier kW | 2.2 | 2.2 | 5.5 |

| Fan kW | 5.5 | 7.5 | 15 |