MGS Series

The MGS Micronizer is a mill model purpose-developed for a micronization which does not require an extreme control of the top-cut or which just requires the reduction of previously ground or fine materials.

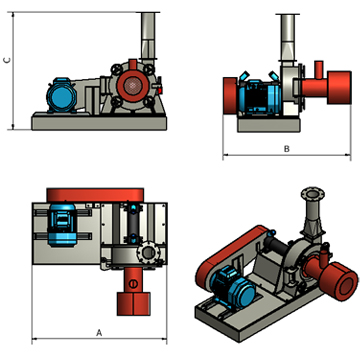

It is a particularly compact machine which is supplied preinstalled on its own easy-to-anchor bed. The extraction and the handling of the micronized product does not require the use of fans for short distances (about 15-20 m).

The efficiency of micronization of MGS mills does not require the presence of the classifier and it compensates its absence.

The particular characteristics are the reduced dimensions, the low power installed and the absence of a fan for the handling of the micronized product thanks to the airflow produced by the micronizer itself.

The principle on which the micronization is based is the high speed impact in a modified grinding chamber in order to improve the trajectories and the redistribution of the material inside.

The internal geometry of the grinding chamber and the rotor have been specifically designed in order to obtain maximum grinding efficacy with one single impact and to generate the airflow necessary for the handling of the material in the grinding chamber.

The horizontal rotation axis allows an easy and quick opening of the grinding chambers, and makes the extraction of the mechanical components easier.

All manual or automatic, starting, regulating, switching off operations can be carried out from the electric switchboard, with the only exception of airflow regulation.

The operating state of the main motor is entrusted to a process regulator and all main parameters are shown on the display.

- The one-rotor MGS micronizer is a compact machine which is supplied already assembled on its own easy-to-anchor bed.

- The feeding dosage takes place by a screw controlled by a process regulator which varies the material quantity according to the consumption value of the grinding motors while keeping it in an optimum range.

- The particular position of the feeder allows the installation of a feeding system on scale and the possibility to verify its weight control.

- In alternative to the grinding consumption a different regulating signal generated by a processing parameter can be used.

- The speed of the grinding rotor is set according to the processed material and it is constant.

- If a self-cleaning bag filter is used for the product recovery, a suction fan is necessary.

- Choice of materials of mechanical parts (Carbon steel or carbide coated steel, AISI 316 steel or special steels which have undergone special heat treatments) according to the application field.

- Cost and managing costs lower than those of MG and MGP models in equivalent sizes

- Limited size and weight

- Easy installation and maintenance

- Easy internal cleaning of the machine which allows the grinding of several products by the same equipment

- Simplicity of the electric switchboard and of the grinding system management

- Possibility to adapt the weight control of the feeding

- Possible adaptation to the grinding of particular materials with different components

| >>> DOWNLOAD DATASHEET | MGS 30 | MGS 40 | ||

| Micronizer | ||||

|---|---|---|---|---|

| Dimensions A mm | 1070 | 1450 | ||

| Dimensions B mm | 1120 | 1370 | ||

| Dimensions C mm | 1000 | 1400 | ||

| Total weight kg | 550 | 800 | ||

| Power supply | ||||

| Grinder kW | 11 | 18.5 ÷ 22 | ||