MG series

The grinding in MG Series classifier mills takes place by high peripheral impact with fixed grinding tools in a circuit closed by a dynamic classifier.

Unlike crushing grinding systems, MG classifier mills can be fed by both grits with a maximum diameter of 15 mm and sands with a diameter of 100 μ. This allows feeding with products of a rough pre-grinding.

At the entrance of the grinding chamber, the material to be processed is immediately sucked by the airflow and parts already sufficiently fine are delivered to the bag filter thereby reducing the workload of the milling.

The peculiar internal geometry of the grinding chamber of G.T.S. classifier mills gives the material hit by the hammers paths which are perpendicular to the impact surface of the armor therefore improving the grinding efficiency.

The horizontal rotation axis allows a quick opening of the grinding chamber, makes the extraction of the mechanical components easier and the servicing operations smoother and faster.

A dynamic classifier, situated on the part above the grinding chamber, allows the continuous control of the final granulometry of the product.

It is made up of a “squirrel cage” wheel which the material must go through in order to leave the classifier mill and which gives the particles a centrifugal force opposite to the kinetic force applied by the airflow on the particles.

By operating on the rotation speed it is possible to change the Top-Cut diameter of the product, that is the maximum diameter of the particles allowed to leave the Classifier Mill.

By combining the design refinement to the building simplicity, MG classifier mills stand out for the high level of their performance.

Their reliability and the consistency of their performances assure a nonstop functioning of many weeks and the necessary planned maintenance takes very little time.

In best conditions of use and maintenance, with materials with a hardness lower than 4° mohs, they guarantee a service availability of 8200 hours/year.

- The one rotor classifier mill is a compact machine which is supplied already assembled on its own easy-to-anchor bed

- The feeding dosage takes place by a screw controlled by a process regulator (PID) which varies the material quantity according to the consumption of the grinding motor while keeping it in the best range. oppure da un segnale regolante differente generato da un parametro di processo.

- The particular position of the feeding allows to install the dosing system on the scale and to carry out its weight control.

- The speed of the grinding rotor is set according to the processed material and it is constant.

- The RPM of the classifier can be changed while the machine is working and the value is shown on the display of the electric switchboard.

- A high head fan is required, specifically dimensioned for the following three objectives:

- Avoid the machine overheating

- Extract the material from the grinding chamber

- Allow the dynamic classification of powders - A self-cleaning bag filter is used for the recovery of the product.

- The parameters to obtain the desired fineness are set and displayed on the operating panel

- Choice of materials of mechanical parts (Carbon steel or carbide coated steel, AISI 316 steel or special steels which have undergone heat treatments) according to application field

- Reliability

- Minimum ordinary maintenance

- Limited size and weight

- Easy installation and access to components

- Change of the product granulometry without stopping production

- Possibility to use feeding weight control

- Possibility to grind different products in the same equipment

- Adaptability to grinding of particular materials with different components

| >>> DOWNLOAD DATASHEET | MG 30 | MG 40 | MG 60 | MG 80 | MG 100 |

| Classifier Mill | |||||

|---|---|---|---|---|---|

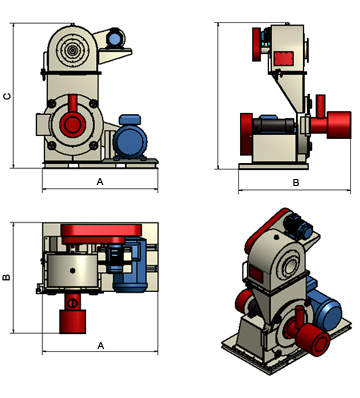

| Dimensions A mm | 1070 | 1450 | 1600 | 2100 | 2200 |

| Dimensions B mm | 1120 | 1370 | 1430 | 1680 | 2110 |

| Dimensions C mm | 1250 | 1405 | 1790 | 2280 | 2770 |

| Total weight kg | 650 | 850 | 1250 | 2100 | 3900 |

| Power supply | |||||

| Grinder kW | 11 | 18.5 ÷ 22 | 30 ÷ 37 | 75 | 110 ÷ 132 |

| Classifier kW | 2.2 | 2.2 | 5.5 | 15 | 22 |

| Fan kW | 5.5 | 7.5 | 15 | 22 | 37 |